MAMBA at a Glance

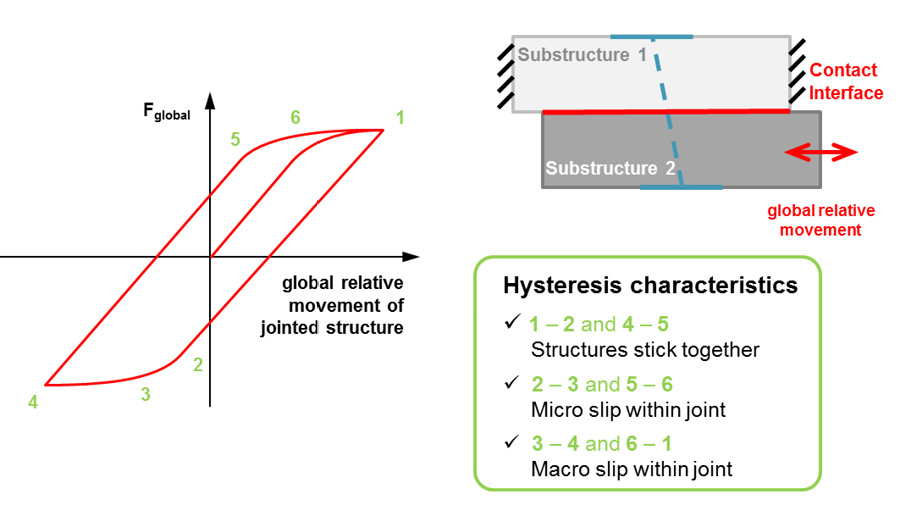

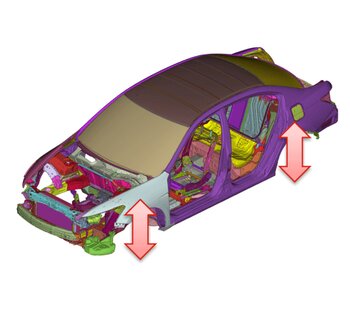

In the development phase of complex mechanical and mechatronic systems reliable dynamic simulation results are of highest importance. A meaningful fatigue assessment of jointed structures like car bodies, truck frames or bolted housings of electronic devices often requires consideration of the occurring contact stresses.

However, the underlying nonlinear contact conditions have the potential to increase the computational effort tremendously. Thus, accurate but still fast numerical models become necessary.

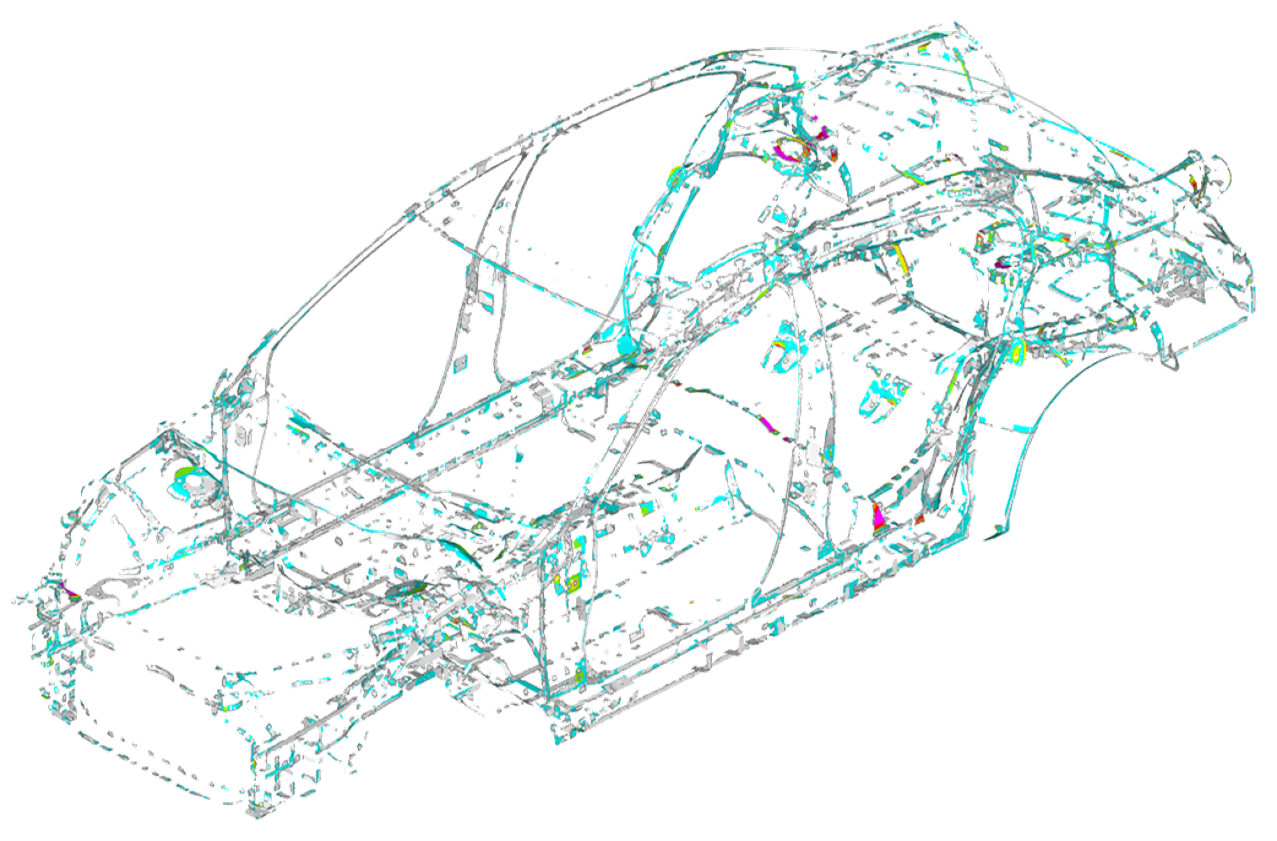

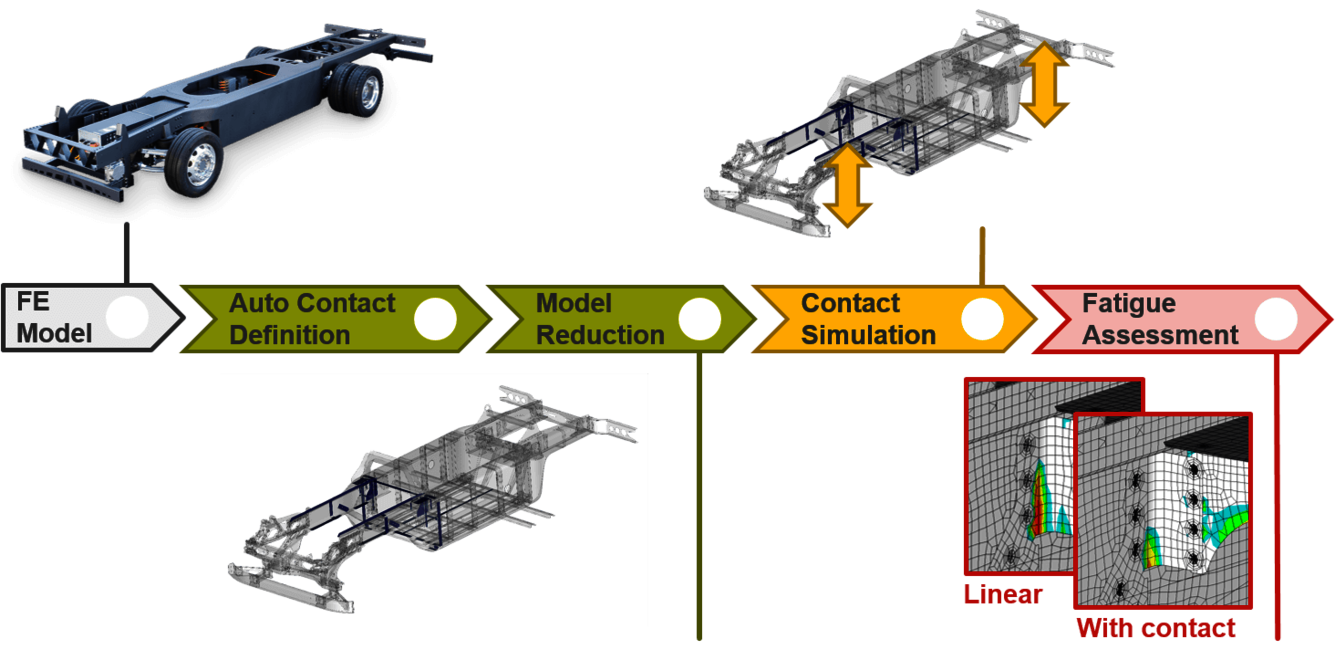

MAMBA is a tailored software solution for this type of analysis. To achieve feasible simulation throughput the contact analysis is performed in two steps. The first one is the identification of the contact interfaces as well as the creation of a reduced order model out of a finite element model for the respective jointed structures. The second step is the contact simulation based on this streamlined model.

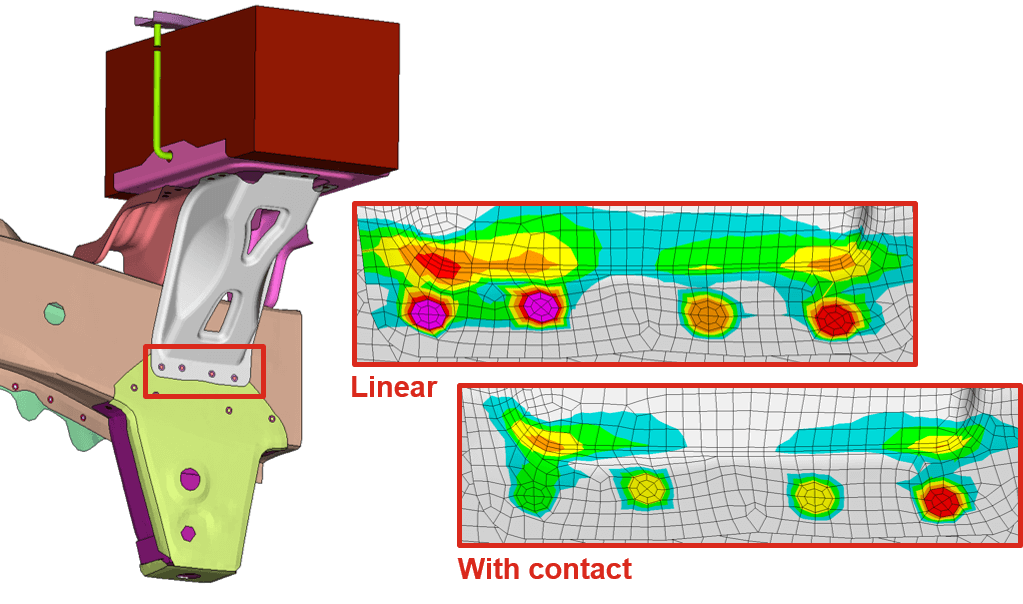

Based on MAMBA the CAE engineer is ready for the dynamic analysis of jointed structures, either for evaluation of the vibrational behavior or for improved fatigue assessment. The next picture illustrates the fatigue assessment results for the battery bracket of a passenger car as an exemplary use case.

Structural Dynamics of Jointed Structures

The MAMBA simulation process for the dynamics of jointed structures consists of two major steps.

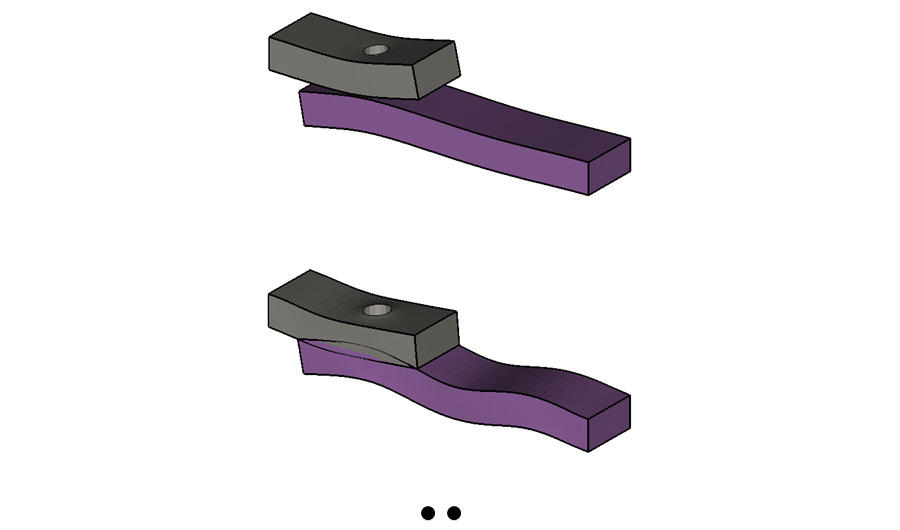

The preprocessing step provides an automated contact interface detection and a nonlinear model order reduction method where MAMBA computes an extended reduction basis. The actual computation of the reduced structural model is carried out by a commercial finite element solver.

The second step is the contact simulation where MAMBA computes the contact stresses. The quasi-static or dynamic analysis of the resulting nonlinear model is either carried out by a commercial multibody system solver or by the internal MAMBA solver.

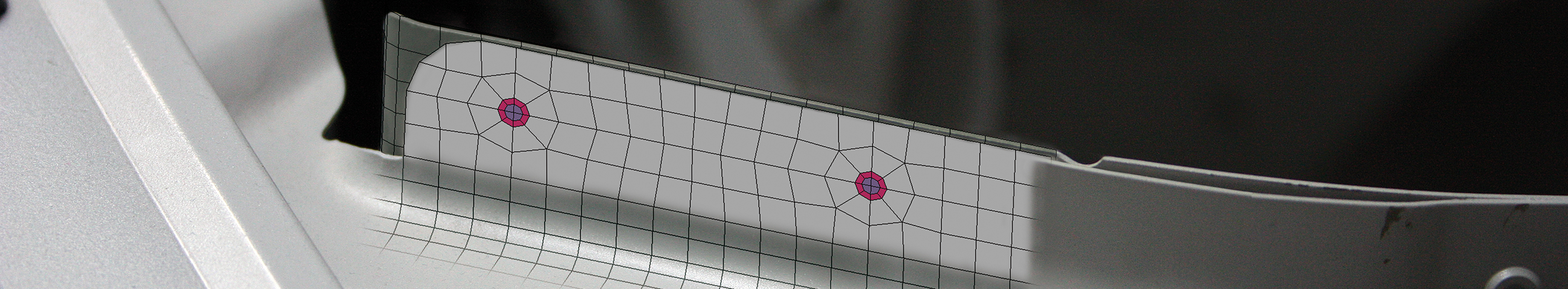

Contact Interface Detection

The MAMBA model order reduction is a modal approach utilizing an extended reduction basis capable of capturing the occurring contact stresses. This functionality is accessible within a preprocessing module that interacts with commercial FEM solvers and offers the following benefits.

- Automated detection of contact interfaces

- Contact ready model reduction

- Pretension of bolted connections

Model Reduction

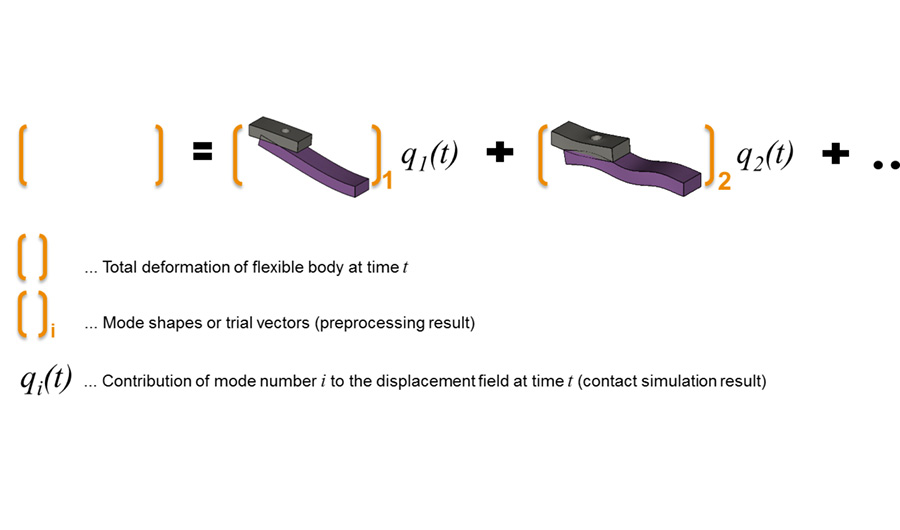

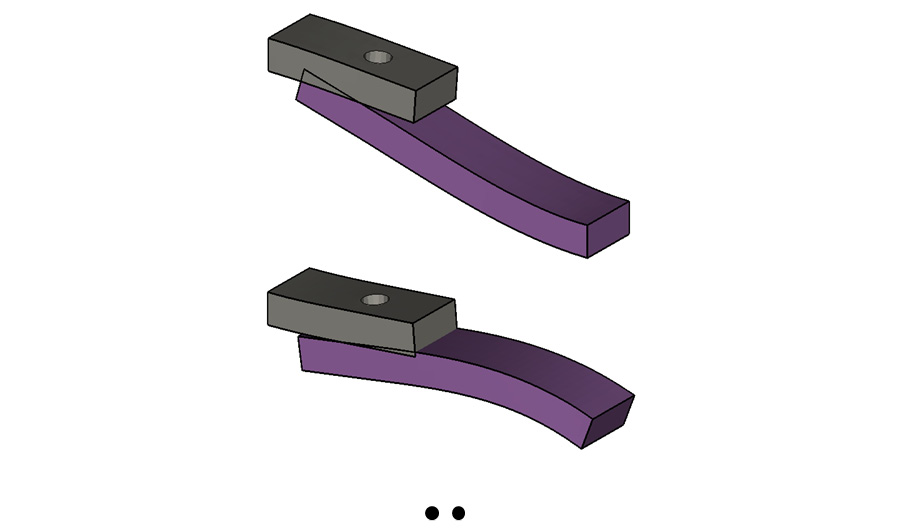

The MAMBA model order reduction is capable of preserving the nonlinear behavior stemming from the contact interfaces of jointed structures.

While the contact interfaces introduce local nonlinearities into a jointed structure the components of the jointed structure can still be assumed as linear elastic. Therefore it is possible to utilize the superposition principle to describe the total deformation of the involved components.

A reduction basis constructed according to Craig and Bampton ensures very good result quality in case of linear elastic structures. This is achieved by the so called constrained modes, which represent static displacement shapes, and boundary fixed normal modes, which represent the internal dynamics of the linear elastic structure.

In case of jointed structures it is also essential that the reduction basis is capable to accurately capture the local displacements due to the occurring contact stresses. This is achieved by an additional set of trial vectors. These so called joint interface or contact modes are formulated to reproduce the local deformations due to the contact stresses. As the structure is capable to deform in a physical meaningful way the computed contact stresses are meaningful as well.

The MAMBA contact simulation relies on the streamlined model for the jointed structure. This model then is analyzed either as part of a multibody dynamics model or as a free body with imposed interface loads. The first analysis setting is denoted as “Multibody Solution” while the second is denoted as “Standalone Solution”.

Contact Models

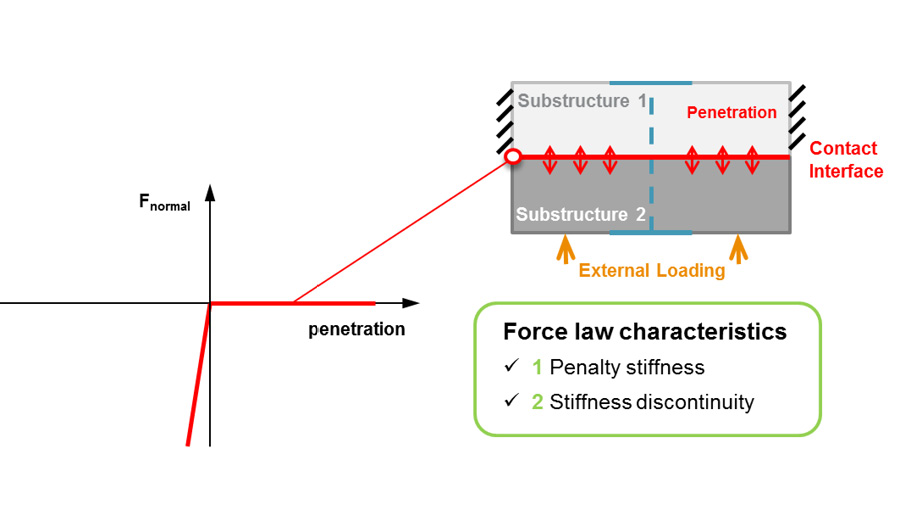

First are contact interfaces where the contact stresses in surface normal direction are the dominating quantity. This is e.g. the case in many areas of spot welded structures. In MAMBA these contact interfaces are denoted as “Normal Contact”.

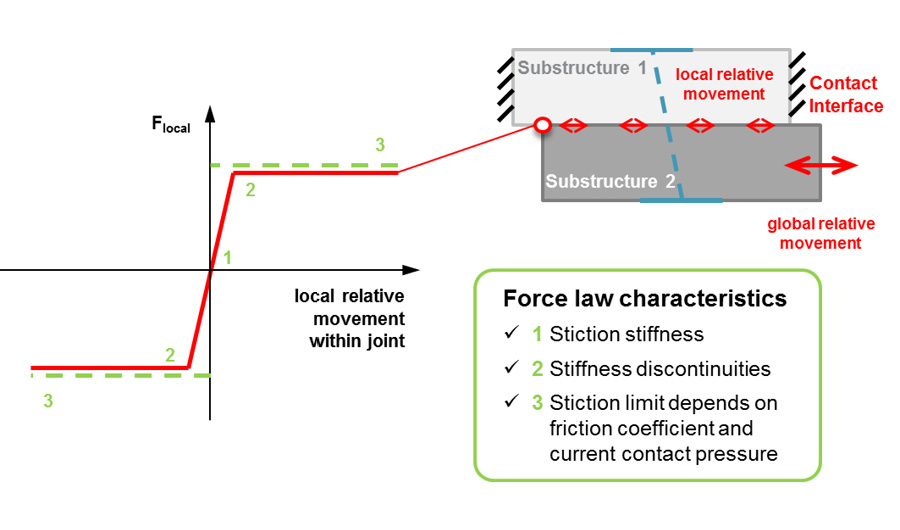

Second are contact interfaces where also shear stresses due to friction are occurring. This is e.g. the case for areas where the external loading would lead to tangential relative movement within the contact interface. In MAMBA these contact interfaces are denoted as “Frictional Contact” and comprise the “Normal Contact” as well.

Third are contact interfaces where high contact pressures values occur due to e.g. pretension of the structure. This is the case for bolted connections which are thoroughly tightened. In MAMBA these contact interfaces are denoted as “Pretensioned Contact” and comprise the “Frictional Contact” as well.

Software Packages

Interested in more?

Downloads

Applications